For my jam idea, I wanted to explore something that would be feasible and practical in the short term. One of the things we do a lot in the lab is mount projectors, cameras, and posters from the ceiling, off of columns, etc. Here are a few pictures from our old space:

I would like to have a flexible way to suspend these things in space, in the position and orientation I want, without having to climb a ladder.

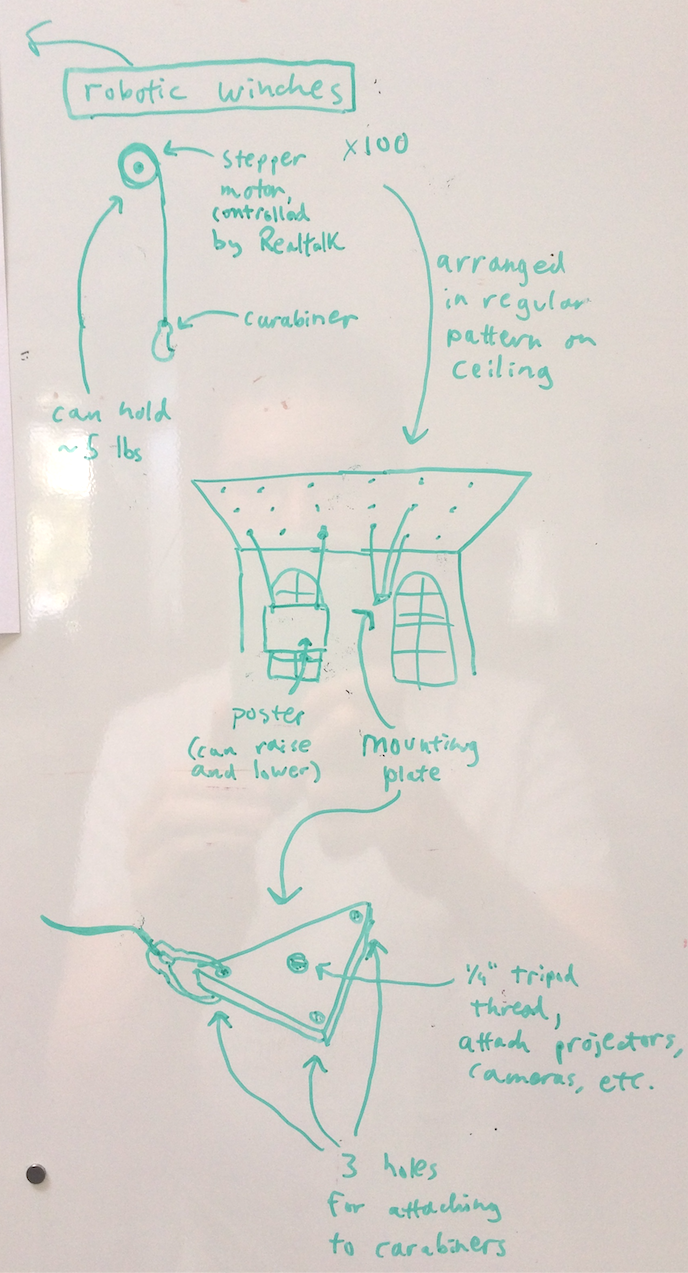

So the idea is to have electronically controlled winches distributed over the ceiling.

When you want to hang a thing, you laser point at 2-3 winches and they drop, you carabiner the cord to your object, then tell the winches to raise the appropriate distance. The winches are of course "objects" in Realtalk and can be controlled or programmed that way. (A use case for this is "storing" foamcore posters on the ceiling and lowering them when you need to refer to them.)

One aspect I explored at the jam was whether having three strings would be sufficient to position and orient one of the triangular mounting plates. From this prototype, you can see that you can position the plate with the three strings, but you have less control over the orientation.

With one additional string, I was able to achieve much more control over the orientation.

I have since convinced myself that 5 strings is sufficient to achieve total control over position and orientation.

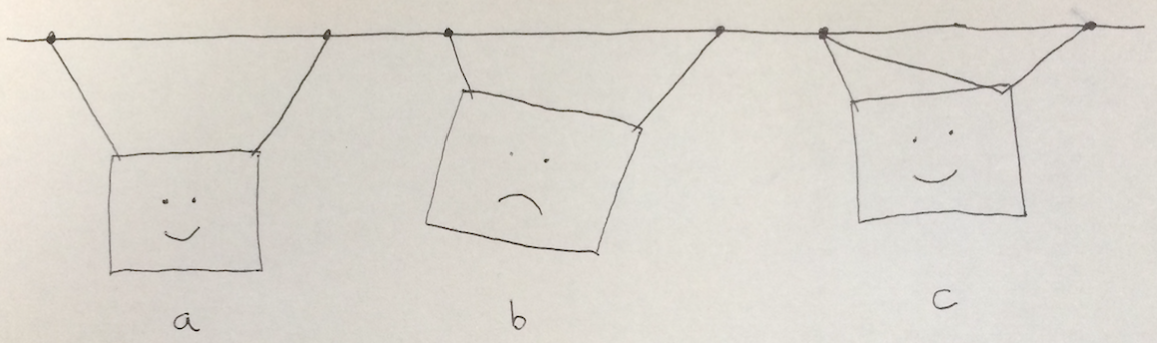

Consider the case where you're hanging a foamcore poster using two winches.

(a) If the poster is approximately centered between the two winches it will hang fine (as in the case with our old research gallery).

(b) However, if you want the poster to be closer towards one side than the other, and adjust by pulling one of the strings shorter, the poster will tilt.

(c) You can correct this by triangulating with a third string.

You can make a similar argument for hanging the triangular mount. Use three strings from two winch points to fix one edge of the triangle between the two winch points. Now its only degree of freedom is radially around the axis formed by the two winch points. You can use two strings from a third winch point to remove this degree of freedom.

It may not be necessary to have total control over the exact orientation of things we hang. We could just hang posters centered between two winch points like (a). And for cameras and projectors we could correct for minor orientation issues by cropping appropriately or using pan and tilt mirrors (which we might want on everything anyway).

One way the winches might be implemented cheaply and effectively would be to use car window motors. These can be had for $10-15 each if we buy in bulk. They use worm gears, which don't back drive, so things won't fall if we lose power. They also seem about the right speed and load for what we're going for.

Since these are DC motors, we could put an optical encoder on the pulley to get a feedback loop around how much we have reeled in the winch. We could also track the carabiners (string end points) with retroreflectors and get feedback this way.

Our lab is ~4500 square feet. I did a cost estimate of what it would take to cover the ceiling with a regularly spaced grid of winches.

Winch every __ ft # of winches Cost at $50 ea Cost at $100 ea

1 4500 $225,000 $450,000

2 1125 $56,250 $112,500

3 500 $25,000 $50,000

4 281 $14,050 $28,100

5 180 $9,000 $18,000

Some points that were made in the discussion:

- Sway could be reduced by using the acceleration strategies that cranes use to not sway their loads.

- The winches could be on sliding rails instead of a fixed grid. This would give us a bit more freedom about where they are on the ceiling. You'd move a winch (without a ladder) by telling it to come down, then pulling it by its end point (so each winch might also need a way to grab/let go of the rail). One thing this complicates is cabling to get power to the winches.