Here's some more journal documentation from my visit to shaper:Here's the plywood, being prepped for cutting. There's a roll of that tape that needs to be put down on the surface of the plywood for the CV. My friend Ilan's in the back there.The domino pattern on the tape is Never Repeated Ever, to facilitate with the positioning identification. I bet you can do all sorts of other crazy things like dating each material and project, etc. since the pattern is unique.This is a shot of Shaper scanning the surface. There is a camera on the other side of that screen. The screen changes perspective based on what you're doing. Right now it shows the plywood piece from a scale that is farther away. When you're cutting the path, it shows you a close-up representation of what you're cutting.The router drill is not in Shaper in the above image. It goes into the cylinder in the center.This is what it looks like when it's cutting: (snapshot of the shaper youtube video, for example)When I was cutting, I initially wanted to look where the router bit was touching the plywood, to see what it was doing. Then I realized that looking at the bit wasn't actually giving me much useful information since the path I'm cutting is only visible on the screen, and isn't on the piece itself. There was this moment where I felt scared to look away from the router bit - I realized I had to look at the screen, and place complete trust in the tool's "eye." I did, and it worked wonderfully. I quickly felt confident that the screen was showing me what it was cutting. You can't see its z-axis, though - you start to go by the feel of the router bit hitting the material, rather then looking at its height.Because the drill bit was .25" thick, the slot that I had made to put the horizontal beams into the frame was not large enough (the diameter of the drill won't fully cut out the slot's corners). Ilan had the idea to create two circles at each end of the slot. Instead of having to go back to the svg file, Shaper can add circles and squares directly on to the piece. So we didn't have to move from the workspace or the tool at all.<-- Two circles at the end of each slot.

The process of routing wood is quite different from laser cutting. (duh) You generally have to go through two passes for a clean cut. Ilan had some tricks for this - on the first pass, you set the bit diameter to .02" bigger than the actual size, which makes the piece .01" bigger. You trim off that .01" on the second pass. An advantage Shaper has over the laser cutter is that it will cut out a shape to its exact size - there's no fudging around with the size on the drawing, because you do not have to take into account the laser's kerf. So the slots that were cut were an exact fit for the material we had. Also, you are not restrained by the 12"x24" rectangle of the laser cutter bed :)Afterwards, Ilan and I geeked out about Tools for Conviviality. Shaper and my/RMO/Dany's initial prototype of the handheld-ink printer are two examples of these machines where humans are enactively empowered by technology, where humans maintain direct control over the tool. I wonder what other examples of digital fabrication tools fit into this category.Let's get one!On Wed, Feb 10, 2016 at 12:57 AM, Virginia McArthur wrote:Love it!

I got bigger foam board for building the paper holding piece that you and Toby mocked up in the furniture jam – I will bring those in tomorrow. The ones that I had ordered were too small. I hope to have that completed by Friday.

VA

From: **************** [mailto:****************] On Behalf Of Paula

Sent: Wednesday, February 10, 2016 12:08 AM

To: Dynamic Medium

Subject: furniture for holding papers

Hello!

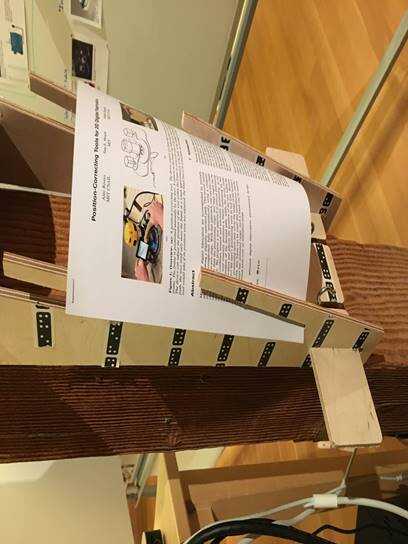

I made a thing using Shaper's router. It is now holding some of our papers.

META! A paper about the paper holder maker:

The tape on the sides of the plywood are what Shaper uses to see the wood. You stick the tape on, and scan it with Shaper. Shaper uses CV to keep track of the router's position.

(It can drill down a variable depth, too. It's like a handheld cnc mill.)

P.S. Tomorrow I'm going to spend the morning reading on the BART. That is, getting on the BART and traveling to the ends of the lines while reading, and then traveling back. You can join me if you want to.

Paula