Context: I'm investigating the idea of a "meta-kit", a kit for making kits, LEGO with laser cutters. So I want to do a few fabrication projects to get my bearings in the space. Also, we need more shelving for all our art/electronics supplies.

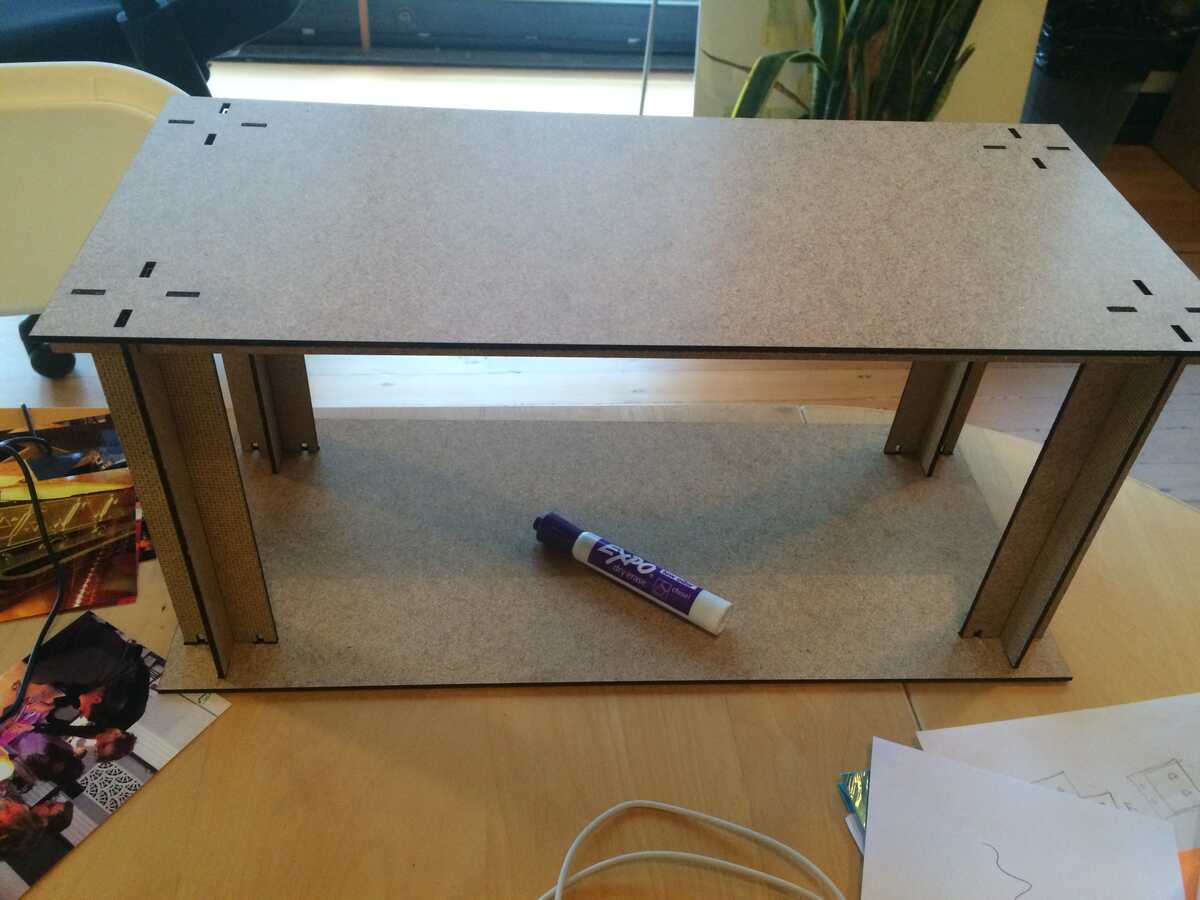

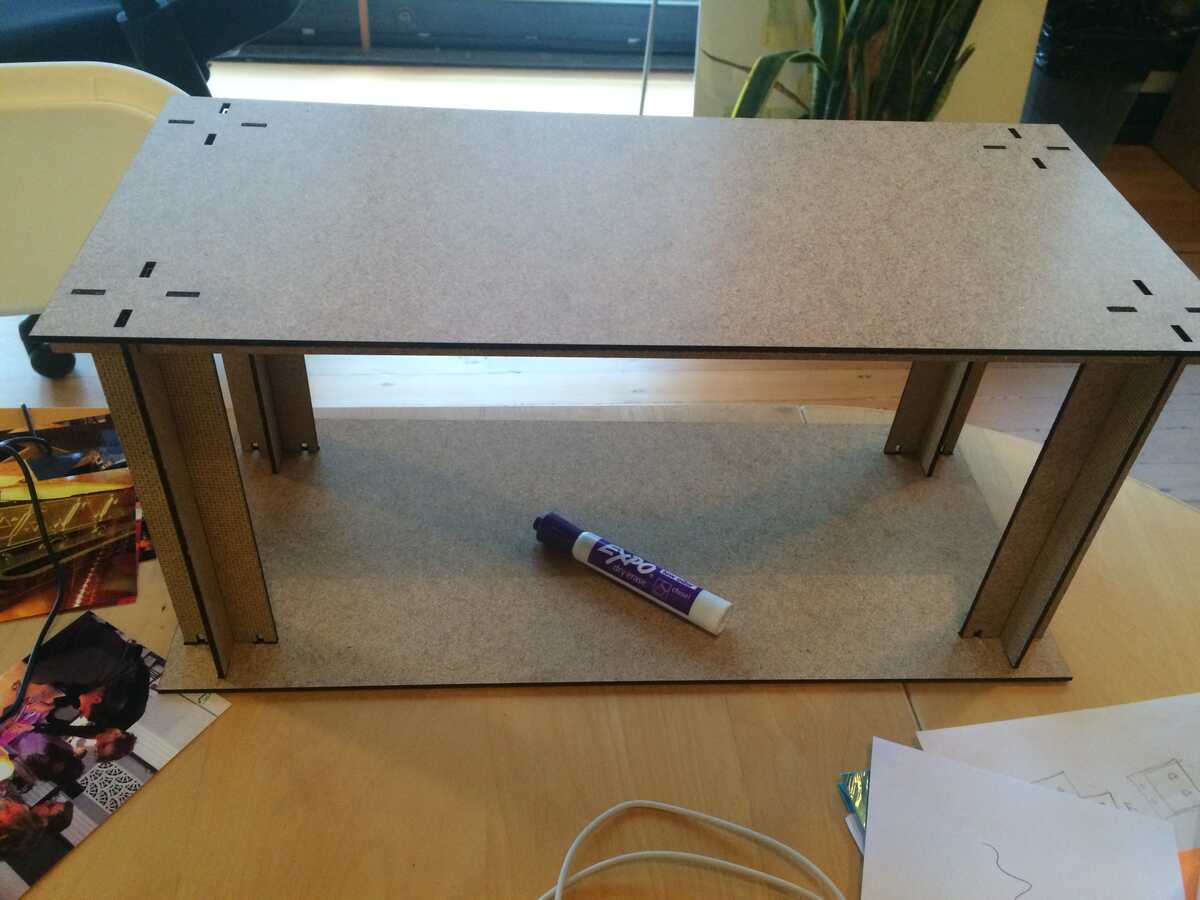

This is my first iteration of a shelf.

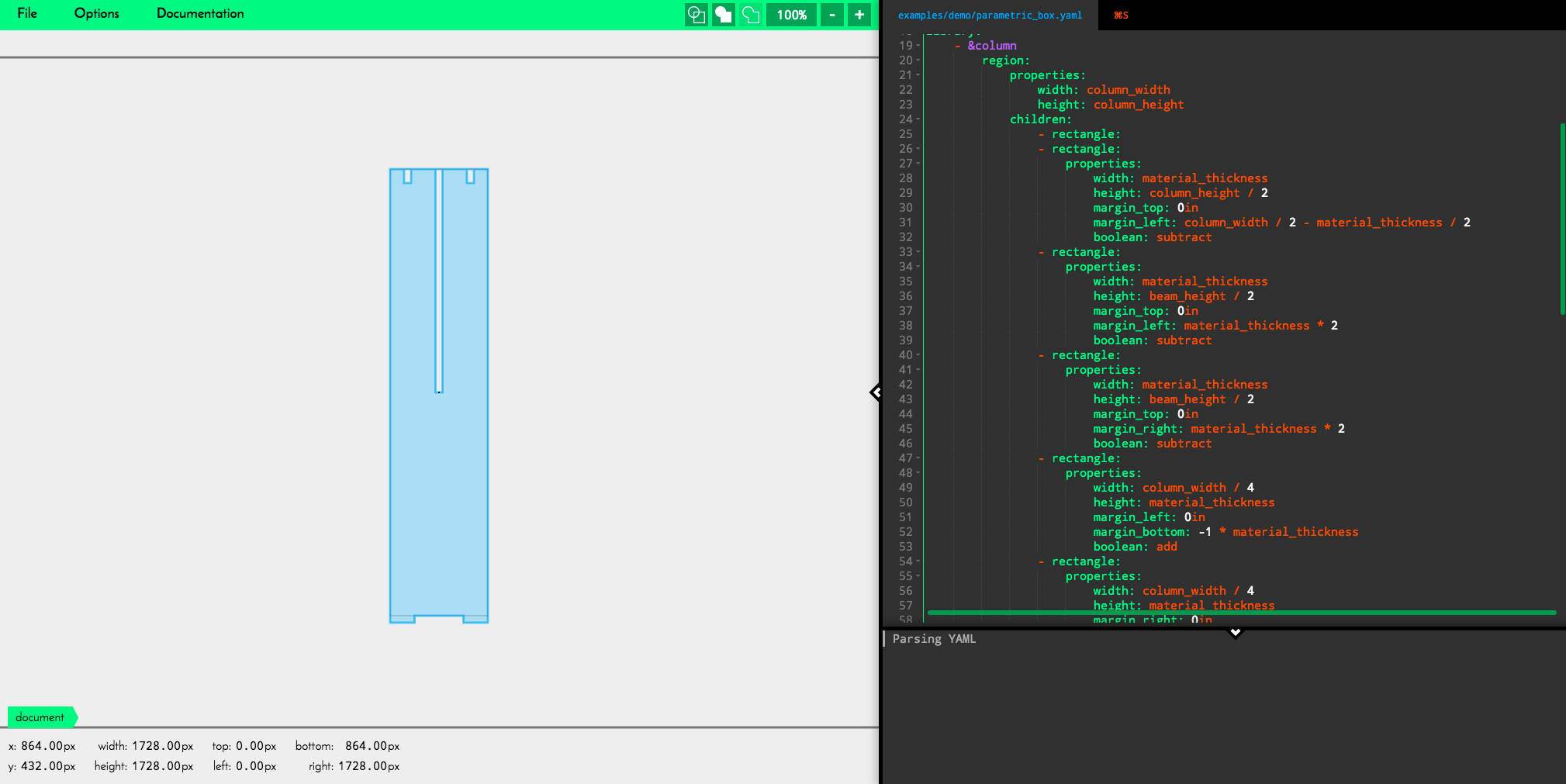

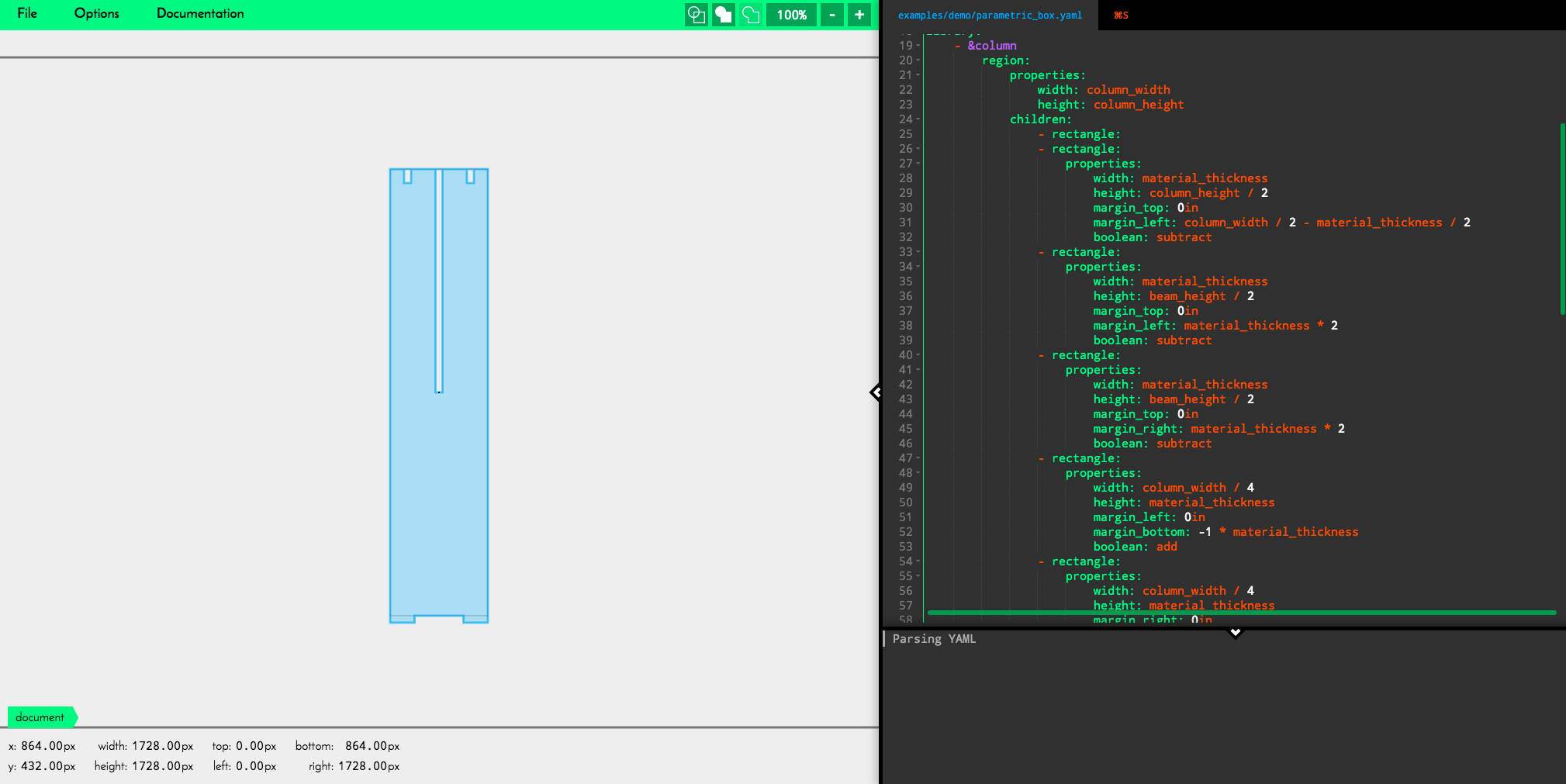

I did the CAD in Combscript, which is a decent abstraction based on nested regions with a live coding interface.

It exports in pixels, at 72dpi. You need to edit by hand the SVG so that the stroke-width is .072 (.001in) and change the height to 864 (12in). Then I was able to use Bret's send-to-laser-cutter script which worked well.

The first iteration has two structural problems.

1. Sag. I have beams going across underneath the shelving floor to try to prevent this but it still sags. I think the simple fix is either more beams or thicker beams (1in instead of 1/2in). Also, the beams are supporting the floor but are not attached to it (the floor just rests on it). I think by attaching it, it will force the beam to stay vertical and not twist in the middle which should reduce sag.

2. Wobble. This is a problem for any big rectangular thing, including the shelves Paula and I rigged to hold the laser cutting materials. The structural fix is diagonal cross beams, but these get in the way of use. My idea to fix it is to have the columns intersect more of the horizontal support by having them attach to the beams rather than attaching to the floor. Thus there will be a skeleton of columns and beams and the floor will just rest on the beams. Since the floor is so thin, it doesn't make sense to depend on it structurally.

Also, both of these issues will improve by using press fit joinery. Right now I've made it so tabs and slots are exactly the same size, but this doesn't take into account the kerf of the cut. Also I'm using .125in as the material thickness, but the material will compress so I should be using a smaller size.